- Highest winding quality with the shortest web paths

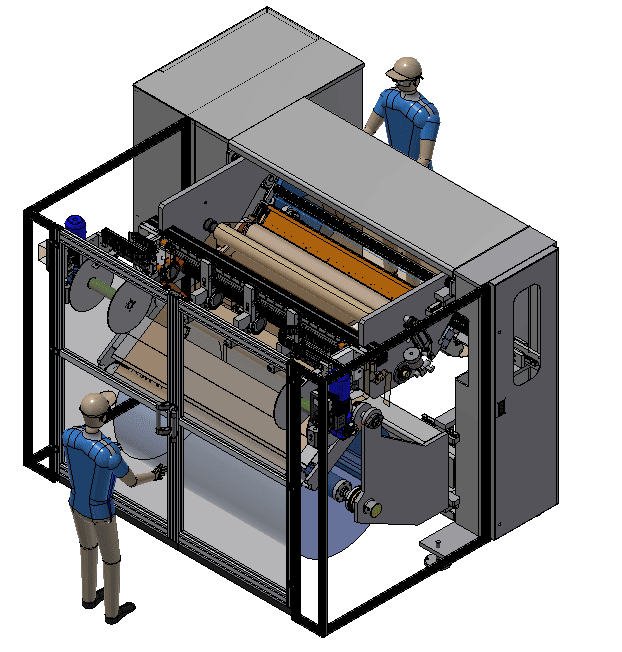

- Few to no glue-touching rollers

- Very short set-up times

- Good overall ergonomics

- Clear and concise construction

- Suitable for almost all web-shaped materials

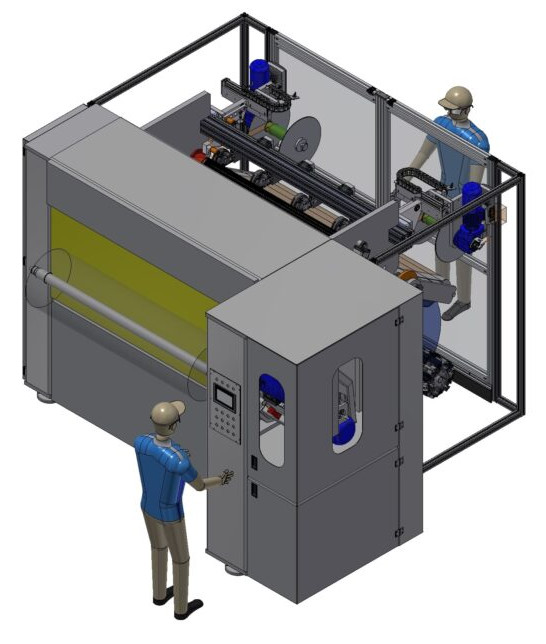

- Execution of the entire machine as a compact machine

- Particularly ergonomic operation of the knife adjustment

- Low-wear

- Maintenance friendly

- High automation grade – thus the entire machine can be operated by one person

- High flexibility and precision

UNWINDER

- Working width: max. 1600 mm

- Jumbo roll diameter: max. Ø 1000 mm

- Unwinding with expansion chucks

- Autom. linear motion control system

- Unwinder with peeling-/dancing roller for constant web tension & control of the winding drive

- Splice table with clamping bars

- Infinitely manually adjustable slitter with measuring scale

- Web separation with high-quality powered banana roller

- Arch height and position adjustable

REWINDING

- Double turret rewinder up to max. Ø 250 mm

- Fully automatic winding system with vacuum suction table

- Fully automatic core positioning

- Fully automatic core feeding from easily adjustable core magazine

Cross cutting as shear cut with a driven circular blade for an absolutely safe and clean cross-section

Fully automatic release pump supply for cross cutting with highly ad hesive materials

- Automatic roll removal with storage table

- Rewinding up to 3 material webs on one winding shaft

Flyer

Basic

- Highest winding quality with the shortest web paths

- Suitable for almost all web-shaped materials

- Clear and concise construction

- Maintenance friendly

- Ergonomic and easy operation

- High flexibility and precision

Flyer